ICRA has a unique sewer-mimicking experimental installation that

consists of a specially designed laboratory and pilot plant

system that reproduces the main characteristics of sewers within

its experimental halls. The pilot plant is basically a direct

connection-extension of the sewer network of Girona that finishes

inside the laboratories of ICRA. The greatest advantage is that

permits to work with real sewage but under completely controlled

operation conditions such as feed pump frequencies, hydraulic

retention times, temperatures, contrary to field-scale sewers,

where natural variability tends to difficult in-depth

investigations.

EURECAT’s facilities located in Cerdanyola del

Vallès include a Robotics and Industrial Automation Laboratory of

500m2, specifically equipped for the design, development,

manufacture, and installation of robotic/mechatronic equipment;

and an advanced manufacturing laboratory (300 m2) equipped for

designing and manufacturing all kind of tools and mechanical

elements. This includes 4 realistic robotic industrial cells with

several industrial and collaborative robots, and Artificial

Vision Laboratory, a lab to develop collaborative applications

and a 100m2 ground/aerial robot test arena equipped with a Motion

tracking system (Optitrack).

FACSA makes its laboratories,

support equipment, hardware, and software (commercial licenses)

available to the project to accomplish both the experimental and

modelling tasks, mainly in WP2, WP3, and WP6. FACSA has several

laboratories where it evaluates the quality of the water. For

this project, it will be used to conduct laboratory experiments

mainly through physical-chemical water. analysis and H2S

measurements. The materials and equipment used are diverse:

jar-test bench, respirometers, digesters, flasks, microscopes,

fluorimeters, etc. It is this equipment and facilities that FACSA

will have available to carry out the project. With regards to

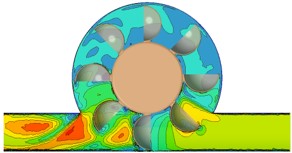

modelling equipment for CFD simulations FACSA has licenses for

CAD: SpaceClaim v19.2 and CFD: Ansys v19.2 and advanced

computational installations including a CAD Workstation for CAD

design, a high-performance computing cluster for scientific

calculations